Submicron | Definition of Submicron by MerriamWebster

Submicron definition is being less than a micron in a (specified) measurement and especially in diameter. How to use submicron in a sentence.

WhatsApp)

WhatsApp)

Submicron definition is being less than a micron in a (specified) measurement and especially in diameter. How to use submicron in a sentence.

The SZ100 nanoPartica DLS system can measure particle size and zeta potential of colloidal dispersions and has the option of an automatic titrator for zeta potential vs. pH studies. The LA960 laser diffraction particle size analyzer is the best choice when particles above 1 micron may also be present in the particle system.

The cavitated particle size distributions of the silver, fumed silica, and micronsized graphene are compared to a 3 roll mill in the first set of graphs below. In all cases, the agglomerate elimination still evident after milling is removed when the material is cavitated, which lowers the effective particle size and tightens the distribution.

How to decrease particle size of alumina powder with ball milling? ... What size media do you have? 8th Aug, 2018 ... I am trying to decrease the particle size to nano scale, using a planetary ...

Ampcera™ LLZO Nano Powder, Aldoped, Li73xAlxLa3Zr2O12, Aluminum Doped Lithium Lanthanum Zirconate Garnet Download SDS Vendor: Ampcera Inc. Ampcera™ LLZO Nano Powder, Aldoped, Li73xAlxLa3Zr2O12, Aluminum Doped Lithium Lanthanum Zirconate Garnet Powder, Solid State Electrolyte for Advanced Lithium Batteries Compositi

The nanoparticle suspensions were then coated onto hydrophilic nanosilica (M5P) coated sub50 micron lactose (Granulac® 200) or potato starch carrier particles in a FB process. Their coating with drug particle nanosuspensions was achieved without appreciable agglomeration, which is .

Sep 13, 2010· This high circulation rate results in a uniform dispersion, narrow particlesize distribution and faster grinding. There are two types of high circulation mills — one uses 3–10mm media to process material down to sizes of a few microns, the other uses media to achieve submicron and nanosize products. MEDIA SELECTION

Nanomilling capability is also in place through a Netzsch DeltaVita® media mill. This equipment provides additional size reduction to nanoscale, and produces development and production quantities. The DeltaVita uses proprietary wet grinding technology to produce batch sizes ranging from 15mL to 300mL, with appropriate processing parameters ...

to produce submicron particle sizes through dry milling methods. Now, when wet media milling is not desirable, it is possible to achieve nanosized particles through jet mills operated with steam. For example, NetzschCondux has devel oped a patented steamoperated fluidized bed jet mill that is capable of producing

Mechanical milling by using planetary ball mill was conducted to reduce particle size distribution and to mechanochemically process CSAC with KOH. CSAC particles reduce its particle size distribution to nano and sub micron size due to mechanical milling.

Nano particle grinding. Special components are available to operate with bead sizes from mm t0 mm diameter. In this bead size range exploratory work can be completed to see what might be possible when Nano particles are required. These parts can be easily adapted to existing Mini Mills or supplied on new equipment.

CPS''s wet processing services include media milling and dispersions. Media milling can produce uniform particle size distributions from micron to 100 nanometer range. In addition to producing nanoparticles, media milling is ideally suited for materials that have the tendency to agglomerate when added to liquid.

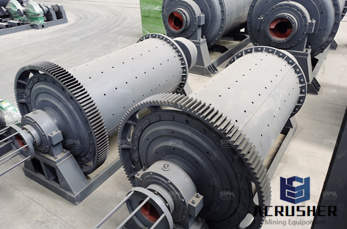

Any of the VKE mills can be run wet or dry, and configured in multiples with a rod equipped rougher mill feeding two fine grind mills equipped with steel balls, ceramic or any type of media that can be used to grind material down to sub micron particle size. Our VibroKinetic Energy Mill is designed for ultra fine pulverization of minerals and ...

Actually, bead mill and sand mill are same machine, They are one of the wet grinding machine, which could reduce the particle size of fluid to micron size or nanometer size. Bead Mills are one of the most effective methods for processing fine particles into submicron or even nanometer size range. A wide variety of designs exist to adapt to the ...

May 01, 2010· The primary reason to select media milling is that the process can produce uniform particle size distribution in the micron and submicron (or nanometer) range. Also, drymilled materials that have the tendency to agglomerate when added to liquid may avoid agglomeration by being mixed with a liquid and processed in a wet media mill.

Alpine M Horizontal Wet Media Mill Size Reduction Milling Chemical Pharmaceutical Mineral The Alpine M Horizontal Wet Media Mill is an agitated media mill with a horizontal, cylindrical milling chamber that is universal in use for the continuous wet milling of particles down to the submicron range.

Cone Crusher Quarry Particle Size Management Media Mill Nano Sub Micron Textile Mill Machinery Aug 08, 2011 · The only English textile museum I''ve visited in person is the Quarry Bank mill at Styal, a National Trust property that a private group furnished with antique machinery and set up to weave reproduction fabric.

Small ceramic, glass or metal beads are agitated inside the mill chamber to aid particle size reduction through impact and energy input while the dispersion is pumped through the mill. Bead mills are one of the most effective methods for processing fine particles into submicron or even nanometer size range.

PARTICLE SIZE MICRONS. Sand Tailings Mist. Ground Limestone. Pollens: Spray Dried Milk ... Asphalt Paving. NOT VISIBLE TO THE EYE VISIBLE TO THE EYE. PARTICLE SIZE CHART. Rain Drops Flour Mill Dust. Insecticide Dust. MERV RATING CHART. Resin Smoke Carbon Black. Tobacco Smoke Soot Blowing Boiler Tubes Bacteria Fertilizer Plant Dust Fumes ...

Particle Size Engineering Through Micronization Center of Excellence for Micronization and NanoMilling Our Center of Excellence in Quakertown, Pennsylvania (USA) is a fullservice provider of particle size reduction and particle size control technologies. With more than two decades of manufacturing experience, we can develop a robust process for

INVESITGATION OF A SUBMICRON MILLING PROCESS OF POORLY WATER SOLUBLE PRODUCTS USING FACTORIAL DESIGN. ... speed of the stirrer in the mill, the grinding media size. The response variables is the time of grinding. ... especially when extra fine particle size as submicron particles are desired.

Alpine M Horizontal Wet Media Mill Size Reduction Milling Chemical Pharmaceutical Mineral The Alpine M Horizontal Wet Media Mill is an agitated media mill with a horizontal, cylindrical milling chamber that is universal in use for the continuous wet milling of particles down to the submicron range.

Beads mill / Ultra fine grinding mill / Nano dispersing mill : ... Drytype fine grinding mill, appricable up to submicron particle size: Fine Mill (Model SF) ↑ TOP: Drytype nomedia grinding machine series: Optimal equipment for the fine grinding of temperature and contamination sensitive materials: Stream Mill (Model ST) ...

4 hours ago· The FlowCam Nano is the world''s first flow imaging particle analyzer that automatically detects, images and characterizes micron and submicron size particles and microorganisms ranging in size from 300 nm to 10+ µm.

WhatsApp)

WhatsApp)