Mill Grinding Course and Kiln Process Program

Mill Grinding Course. PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course.

WhatsApp)

WhatsApp)

Mill Grinding Course. PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course.

Columbia Steel offers a full line of wear parts for rod mills, ball mills, and semiautogenous grinding (SAG) mills for cement plants. Made in USA. Columbia Steel Casting Co., Inc.

Dec 12, 2016· Introduction. Cement grinding mill is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as cement Cement Grinding Mill_ Yuhong Heavy ...

Cement mill is also called cement ball mill, which is mainly used for grinding cement clinker in the cement production process. It is one of the important cement equipment. The output of cement mill is 21~155 t/h, and the specific surface area of cement is 3300~3800 cm ² /g.

important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media . Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills

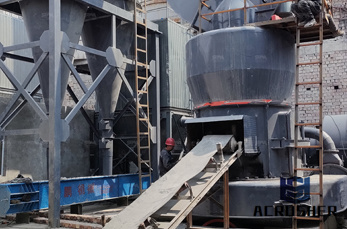

Grinding Mill Machine in Cement Production. Zenith provides both large scale and small scale cement production plants for sale, which are available with crusher plant, cement grinding mill, ball mill, vertical roller mill, rotary kiln etc.

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

The new Mill Audit Expert (MAE) software: Some examples of axial tests and possible causes of malfunction. Advertise with us. Axial test Interpretation: The Art Of Sharing and...Imagination. The Cement Grinding Office. Our reference list A series of real examples are exposed and interpreted. We also prove the impossibility of automating ...

May 11, 2015· a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12]. A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder. Grinding Aids are used to improve the grinding efficiency and reduce power consumption. This paper discusses the grinding aids mechanism and

Description Model # 50200HD. Perfect for indoor surface grinding applications, including garage, kitchen, basement or patio; Grinds down concrete high spots, removes sealers and thin mil paints, removes mastics and preps floors to accept new coatings

Jan 07, 2015· CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll . ... Calculate the charge of grinding balls of a threecompartment mill for dry grinding of cement raw mix. The mill feed is a medium hard raw material with a particle size of minus 1 inch. Mill diameter is meter and the useful mill length ...

* Mill internals, media, liners and diaphragms. * Ventilation, cooling and drying. * Control concepts. * Grinding aids and other tools to boost efficiency. Module 3 – Vertical mills. This module will cover the technology of vertical mills used for raw and finish grinding in the cement manufacturing process.

The Preliminator mill is a type of ball mill used for coarse grinding in open circuit or for fine grinding in closed circuit. Preliminator mills are widely used in the cement industry for the reduction of cement raw materials and clinker. It is also used for the reduction of abrasives, refractories, limestone for .

Most importantly, the mills are customisable to each unique mining application, optimizing the performance of the mill and recovering more ore for your business. Our stirred mill and tower mill solutions offer a range of advantages, designed to optimise your milling while solving a number of issues traditionally related to industrial grinding:

Mar 08, 2013· re CALCULATION OF BALL MILL GRINDING EFFICIENCY. Please can anyone give me, step step by procedure on how to work out on cement ball mills to. improve it''s efficiency, optimum operation and increases output.

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %.

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the .

Jun 07, 2018· The OK mill has been FL''s standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding, designed with the same proven ...

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process ...

Lvssn provides various grinding equipment for cement production line, including: Grinding mill,Ball mill,Rod mill,Roller press,Veritcal mill,Pipe mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given. A case study performed on a typical energyefficient Horomill® grinding ...

WhatsApp)

WhatsApp)