installation of ball mills

large ball mill installation. large ball mill installation offers 536 large cement mill grinding balls products. About 80% of these are cast amp; forged, 1% are ceramics, and 1% are abrasives. Get Quote

WhatsApp)

WhatsApp)

large ball mill installation. large ball mill installation offers 536 large cement mill grinding balls products. About 80% of these are cast amp; forged, 1% are ceramics, and 1% are abrasives. Get Quote

Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, roundtheclock reliability and the opportunity to mine in remote areas. This makes low ore grades economical to grind. ABB has delivered some of the world''s largest GMDs: • 22 MW GMD for 28'' ball mill

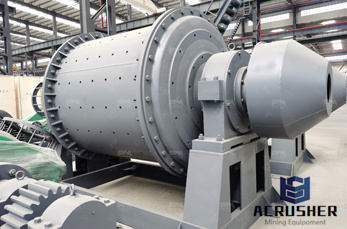

Ball Mill Operation. Ball mills ride on steel tires or supported on both ends by trunnions. Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive. The prime movers are usually synchronized motors. During rotation, a portion of the charge is lifted along the inside perimeter.

In the past, grinding mills operating between 18 MW and 28 MW required a large electrical wraparound motor, known as a Gearless Mill Drive (GMD). The QdX4 is an alternative option to the GMD. Until now, the geardriven solution for large SAG and ball mills was limited to 18 MW.

The IsaMill is a stirredmedium grinding mill, in which the grinding medium and the ore being ground are stirred rather than being subjected to the tumbling action of older highthroughput mills (such as ball mills and rod mills). Stirred mills often consist of stirrers mounted on a rotating shaft located along the central axis of the mill.

offers AG mills, SAG mills, ball and pebble mills, and stirred mills to your needs. By continuing to use the site, you agree to the use of cookies. ... grinding mills are available at a low total cost of ownership due to low installation and operating costs, as well as simple maintenance.

These ballnut stops replace the original brass acme nuts. ... After using my mill manually for a few tasks, I began to despise the play in the ACME ball screws. ... but mine lacks flanges. The bearing spacer acts as a lower flange, so it''s not an issue. To align the pulley, I chucked the bearing spacer, put slow CA adhesive on the pulley

Ball Mill For A Gold Mine. casting equipment for graphite mine in trinidad and tobago gold mine ball mill prices are used for how much is a ball mill used in graphite mine in Get Priceign Up to Team Appign Up to Team Appe ask for these details so your team will know who you are and so you can get access to all information your team publishes.

Looking for affordable ball mill prices? 17,274 low price ball products from 5,758 trustworthy ball suppliers on Reach out to suppliers directly .

We offer autogenous (AG), semiautogenous (SAG), ball, rod, and pebble mills in sizes ranging from kWs up to 30+ MW. Our product range also includes a number of unique solutions, including the world''s largest acidresistant grinding mills, which can operate with extremely corrosive slurry.

10,000 TPD Gold Plant w/SAG Ball Mills, Gyratory Cone Crushers, Rock Breakers More, UNUSED ANI MINERAL PROCESSING '' x 43'' Ball Mill 13,400 HP, UNUSED 22'' x 38'' Ball Mills and 36'' x '' SAG Mill

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

COPPER MOUNTAIN: OVERVIEW ON THE GRINDING MILLS AND THEIR DUAL PINION MILL DRIVES *M. van de Vijfeijken1, ... ball mills. The installation and commissioning of the mills and drives at Copper Mountain will be briefly ... 35,000 tonnes per day mill. The mine with an estimated resource of 5 billion pounds of copper is designed

Feb 12, 2017· In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

offers 6,456 gold mining ball mill products. About 80% of these are mine mill, 2% are other fabrication services, and 1% are grinding equipment. A wide variety of gold mining ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

Theories of ball wear and the results of a marked ball test . SAIMM. explained, and it is demonstrated that the ball consumption in a ball mill can be predicted with fair accuracy from the results .. where 0 is the cost per ton of balls to the mine.

Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors. Xinhai equipment mainly include: ball mills, flotation, thickeners, and so on.

Mineral Processing EPC. Xinhai EPC provides services of sample test, mine design, equipment manufacture, etc. for clients, and solves the common problems in plant construction such as budget overrun, schedule delays, unqualified equipment, unclear recovery benefit, disputes of the manufacturers, and unclear responsibility of aftersale service

ball mill structure parts installation. Home; ... Mine Crusher. Meanwhile, ball mill are very popular, too It can easily ground the gold ore to small particl At the bottom of ball mill, one wire mesh is installed, so it separates the qualified ones directly before discharging them from the machine Actually, ball mills,

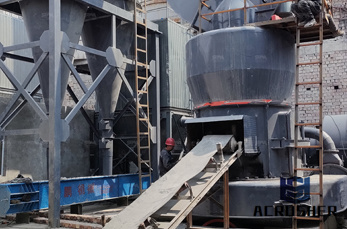

Enhancement of mining process and installation of a ball mill at the ... Enhancement of mining process and installation of a ball mill at the Matagami Mine. Norda Stelo was ... Xstrata Zinc Canada; Matagami, Quebec, Canada. Get Quote

Sep 13, 2016· Owner of a private cut and fill gold mine gives us a detailed tour, demonstrates tools, equipment, construction and the geology of his mine. Some of .

Dec 18, 2012· This will hold the ball screw in place while you stand your mill back up. Stand the mill upright; have a friend help to gently set the base down. Slide the saddle forward, so that the ball screw is now sticking out the hole in the base far enough to slide the Yaxis motor mount onto the end of the ball .

The Kaltech Intelligent Bolts, both the iBolt and the eBolt, present a true breakthrough in the real time wear monitoring of the mill liners, for the very first time. As the exclusive providers of this technology to milling operations globally, Kaltech is proud of the enhanced value we can bring to clients.

In many grinding plants mills which have metallic or rubber liners suffer from bolt breakage. Our technicians come across broken mill bolts at many sites around the world, to the operators of the mills it is an almost normal occurrence, but if you have breaking bolts there is an underlying problem which needs to be fixed.

WhatsApp)

WhatsApp)