(PDF) Recovery of Metals from Aluminum Dross and Saltcake

Fine Black Dross . ... Aluminum dross is a recyclable byproduct of the aluminum manufacturing process. Since the use of aluminum alloys increased in large ...

WhatsApp)

WhatsApp)

Fine Black Dross . ... Aluminum dross is a recyclable byproduct of the aluminum manufacturing process. Since the use of aluminum alloys increased in large ...

whereas black dross has a lower metal content and is generated during aluminium recycling (secondary industry sector). White dross may contain from 15 to 70% recoverable metallic aluminium and it comprises a fine powder from skimming the molten aluminium 1. Black dross

The salt removal from black dross by thermal treatment has experimentally been studied under different conditions in both a stationary resistance furnace and in a laboratory scale rotary furnace.

More than a million tonnes of aluminium black dross (ABD) are reported throughout the world each year, and around 95% of this material is landfilled . Typically, ABD contains aluminium metal (10–20%), a saltflux mixture (40–55%), aluminium oxide (20–50%) and other contaminants and is one of the major waste byproducts in the production ...

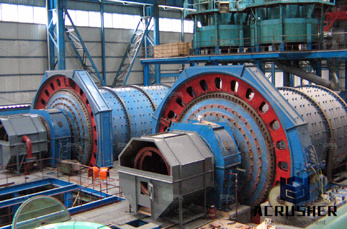

aluminum chromite mining plant for sale. Cold aluminium dross ball mill and sieving machine. Cold aluminium dross ball mill and sieving machine The main purpose is to crush and grind cold dross and sieve in different grades and separate in coarse medium and fine dross The coarse aluminium dross can be recycled in the melting furnace the medium dross can be used in the dross processing .

Aluminum Briquetting: Squeeze Value From Aluminum Waste. No matter how you slice it, manufacturing aluminum products leads to aluminum and fluid waste. Aluminum Briquetting Aluminum scrap metal, in the form of turnings, filings, chips and shavings, is produced every day of production, piling up on the equipment. Aluminium Powder Briquetting Machine

High speed dross. If the cutting speed is too fast, the arc begins to lag back in the kerf leaving a small hard bead of uncut material or rollover dross along the bottom of the plate. This highspeed dross is more tenacious and usually requires extensive machining to remove.

aluminum dross grinding Bridge I. Aluminium dross grinding and cooling machine . Aluminum dross processor from Brightstar Aluminum Machinery by alumachine. 236 views ... Aluminium dross ... aluminum dross briquetting press_ Aluminum dross is the mixture ...

High quality briquetting systems increase efficiency and yield. Aluminum''s recycling cycle begins and ends in melting plants. In between, this light metal is machined in many different industrial operations of diverse branches and ideally is then pressed into a compact briquette using a briquetting system from German provider RUF.

Crusher Machine For Fine Aluminum Dross K C3 Bcchen. The product contain coarse and fine particles. a ball mill is based on impact. jaw crusher. is a schematic diagram of a jaw crusher. fig jaw crusher . a jaw crusher consists of a vertical fixed jaw and another swinging jaw that moves in the horizontal plane. in the diagram above, the jaws are coloured red.

Coke fine briquette machine – set up briquette plant with roller press Coke fine briquette machine is used to recycle the coke fine which is treated as a waste in the industry. The selling price is very low for this waste compares to the lump coke, but briquette work changes this condition and turns it to be a useful and valuable resource.

Founded in 1989, the Chicago Heights facility is a secondary aluminum recycler, with two rotary furnaces and two holding furnaces. It has the ability to process a wide range of aluminum scrap and dross, and produces RSI sows, deox shots and deox cones. ISO9001 REAL ALLOY RECYCLING, LLC 400 E. LINCOLN HWY. CHICAGO HEIGHTS, IL 60411 PHONE 708 ...

aluminum ash briquetting machine price, offers 75 aluminum ash briquette machine products About 81 of these are briquette machines 12 are energy saving equipment and 1 are biomass briquette machines A wide variety of aluminum ash briquette machine options are available to .

The metal content of the black dross will vary depending on the scrap type being charged and the processing conditions, but varies from 7 to 35% and in special circumstances as high as 50%. The oxide content of the black dross will be approximately equal to the salt flux content. The related information. Aluminum dross recovery system

dross press, dross press Suppliers and Manufacturers at ... We are a small factory but dedicated in only roller compactor for granulating briquetting powders Pressed aluminum dross balls Ball press machine specs. 360mm 504mm 600mm 650mm Rollerwidth 180mm 300mm 310mm 330mm Roller speed 1622rpm 1420rpm 1218rpm 1016rpm Screw feeder power 11kw 11kw 15kw Pressure .

Carbon black has higher calorific value, fixed carbon and low sulphur and ash content; it can be potentially used as high quality fuel either in briquettes. The briquette making of fine carbon (powder form) from scrap tyre pyrolysis plant is slightly more difficult than production of .

offers 177 aluminum dross ball press machine products. About 1% of these are Briquette Machines. A wide variety of aluminum dross ball press machine options are available to you, such as applicable industries, warranty, and showroom location.

Hydraulic Metal Chip Iron Copper Aluminium Scrap Briquetting Machine Price In Canada. is a company with a history of more than 125 years and is recognized as the leader in mechanical briquetting, a position that has been created through more than 70 years of experience developing, producing and selling high quality briquetting machines.

We are a small factory but dedicated in only roller compactor for granulating briquetting powders Pressed aluminum dross balls Ball press machine specs. 360mm 504mm 600mm 650mm Rollerwidth 180mm 300mm 310mm 330mm Roller speed 1622rpm 1420rpm 1218rpm 1016rpm Screw feeder power 11kw 11kw 15kw Pressure of accumulator 56Mpa 610Mpa 810Mpa 812Mpa Linear .

, Recovery of Metals from Aluminum Dross and Saltcake 51 Flowsheet of Eddy Current Separation Process Circuit 1 flowsheet White dross and black dross samples processed using Circuit 1 (Figure 1), were crushed to 6" and then screened at 2". The +1/2" fraction and 1/2" fraction were

Separation of aluminum from fine granules of black dross, which is a waste byproduct in secondary aluminum production, was investigated. The separation was performed by a multistage electrostatic separation method. There are three stages to complete the separation, including preliminary separation, pulse charging enhancement and secondary concentration.

aluminum dross briquetting machine aluminum ash. Aluminum dross or aluminum ash is the mixture of metallic aluminum and nonmetal part mostly aluminum oxide Dross is formed on the surface of molten aluminum or its alloys by oxidation It is a valuable byproduct of any aluminum smelter or aluminum foundry which is recycled to recover the valuable ...

Various aluminumsmelting byproducts from three production sources were received and characterized. The waste materials were tested for compound identification and environmental acceptance. A coarse metallic aluminum recovery test using an Eddy Current separator (ECS) was performed using two different Circuit configurations. White dross performed equally well with either Circuit, while black ...

Aluminyum Dross Briquetting BRIQUETTES FROM THE WITHOUT SALT ALUMINUM DROSS Our project can be defined as; sort out aluminium white dross and salt slag (black dross) with mechanical seperation for metallics and additionally dissolve / leach salt additions to gain salt and clean oxide and finally press clean oxide mixtures at our roll press in ...

WhatsApp)

WhatsApp)