Types of Iron Ore: Hematite vs. Magnetite | INN

For that reason, hematite ore is important for many mining Australia''s Magnetite Network explains, "[d]irect shipping ores, when mined, typically have iron (Fe) content of between ...

WhatsApp)

WhatsApp)

For that reason, hematite ore is important for many mining Australia''s Magnetite Network explains, "[d]irect shipping ores, when mined, typically have iron (Fe) content of between ...

The Flowsheet for Hematite Benefication Process by Flotation The above flowsheet has been developed to produce a high grade product economically with maximum recovery. Due to the flexibility of Units and especially the "SubA" Flotation Machine, gravity flow can be utilized throughout the mill, thus keeping pumping requirements to a minimum.

China Hematite Iron Ore manufacturers Select 2019 high quality Hematite Iron Ore products in best price from certified Chinese Mining Equipment manufacturers, Mineral Processing Machine suppliers, wholesalers and factory on

Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle, ore with small amount of magnetite and the gangue minerals containing quartz or kaolin.

Mar 14, 2014· Mining of Iron Ores. satyendra; March 14, 2014; 0 Comments ; Hematite, Iron ore, mines, mining, Mining of Iron Ores. Iron ore is a type of mineral and rock from which metallic iron is extracted economically. This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty red.

Mining (EHM) orebody The EHM orebody is an iron oxide copper gold (IOCG) deposit with magnetite being the form of iron ore. EHM''s Ore Reserve Estimate at 30 June 2010 is 88 million tonnes at a grade of 1% copper, grams per tonne gold and 23% magnetite. In 2010, EHM produced 74,595 tonnes of copper in concentrate and 91,259 ounces

Increasing iron ore demand, coupled with the depletion of highgrade hematite ores in the United States, after World War II led to development of lowergrade iron ore sources, principally the utilization of magnetite and taconite. Ironore mining methods vary by the type of ore being mined.

The Brockman Iron Formation in the Hamersley province is a significant example of high grade hematite iron ore deposits. Magnetite is an iron oxide mineral which is generally black in colour and highly magnetic, the latter property aiding in the beneficiation of magnetite ores. Magnetite mineral contains % iron, which is higher than ...

Iron ore,hematite mining,magnetite process,siderite,pyrite, hematite hematite, also spelled as haematite, is the mineral form of ironiii oxide et more hematite iron ore mining process, understanding iron ores and mining of iron ore hematite is one of the most important iron or the process of mining iron ore requires massive resourcapr. Chat ...

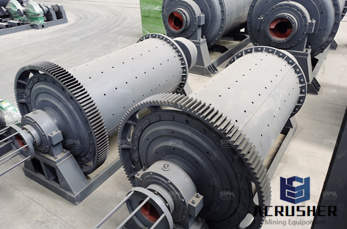

At the processing plant, the taconite is crushed into very small pieces by rock crushing machines. The crushers keep crushing the rock until it is the size of a marble. The rock is mixed with water and ground in rotating mills until it is as fine as powder. Separation The iron ore is .

About product and suppliers: offers 150 hematite iron ore processing products. About 10% of these are other mining machines. A wide variety of hematite iron ore processing options are available to you, There are 150 hematite iron ore processing suppliers, mainly located in Asia.

Oct 08, 2011· Iron Ore mining in the Plibara region of Western Australia near Newman. The Mt. Whaleback, Yandi, and Area C mines are shown.

Cast iron has already been mentioned above. This section deals with the types of iron and steel which are produced as a result of the steelmaking process. Wrought iron: If all the carbon is removed from the iron to give high purity iron, it is known as wrought iron. Wrought iron is quite soft and easily worked and has little structural strength.

Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining. The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron ore.

Operations consist of an open pit truck and shovel mine, a concentrator that utilizes single stage crushing, AG mills, magnetite separation and floatation to produce hematite and magnetic concentrates that are then supplied to the onsite pellet plant.

Magnetite ore often occurs in metamorphic rocks, which formed from ferruginous sediments in both regional and contact metamorphic settings. It is commonly formed by the reduction of hematite and ferric hydroxide minerals in these rocks. Banded Precambrian iron formations commonly contain magnetite ore.

Process of mining hematite hematite iron ore mining process . Hematite A primary ore of iron and a pigment mineral Geology. Hematite is the most important ore of iron and it has been used by people as a pigment investments allow companies to efficiently mine and process the ore.

Mining and processing hematite and magnetite ores. Hematite: A primary ore of iron and a pigment mineral Geology . Hematite is the most important ore of iron and it has been used by people as a pigment for at ... equipment investments allow companies to efficiently mine and process the ore. .... Hematite is mined in some of the largest mines in ...

Iron ores are rocks and mineral deposits from which clanging iron can be reasonably extracted. Iron ore mining is classified into two categories manual mining and mechanized mining methods. Haematite and magnetite are the most commonly found iron ore minerals. Deposits of iron ore such as haematite containing iron oxide are found in sedimentary rocks from which the oxygen is removed from the ...

what is the process of mining hematite. Process Of Mining Hematite what is the process of mining hematite hematite iron ore mining process gujaratgenomics. iron ore hematite mining process iron ore hematite mining process Hematite By John Inmon Emporia State UniversityDec 6, 2003 The main focus of this page is the [Get More] NEXT PAGE: machines for .

Hematite Iron Ore with Fe2O3 chemical formula is known as very high iron content with about 70 percent. One of the major advantages of hematite Iron Ore over the other types is its high iron content. Its name root is from the " haima" which is a Greek word with blood meaning, due to its red color.

Building the Next Iron Ore Mine Champion Iron Mines Limited. company with projects located in Canada''s premier iron ore mining district at the southern ... The coarsegrained hematite mineralization produces a concentrate that qualifies as a ...process and directly fed into a blast furnace to make steel.

Typically, hematite is mined by open pit mining. Overburden is removed, then the ore is mined from an everdeepening hole. The mineral and rock is first stripped by blasting the rock with explosives and removing it with enormous trucks with capacities over 150 tons. The ratio of mineral to rock can be quite large up to to 1 for hematite.

Iron Ore Introduction: Ore, which contains an economical use of iron, is called an iron ore. There are many types of iron ore, magnetite (Fe3O4), hematite (Fe2O3) and (FeCO3), etc, which are mainly used for iron making. Iron ore is an important raw material for iron and steel production enterprises.

WhatsApp)

WhatsApp)