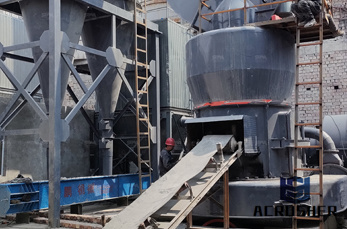

grinding mill roller

grinding mill roller_Polysius Roller Mills. For grinding5 The core components of the roller mill include: xthe wearprotected grinding table with double groove grinding track xtwo roller pair units whichGRINDING MI

WhatsApp)

WhatsApp)

grinding mill roller_Polysius Roller Mills. For grinding5 The core components of the roller mill include: xthe wearprotected grinding table with double groove grinding track xtwo roller pair units whichGRINDING MI

Polysius Roller Mills. For grinding. 8 Polysius roller mills..for raw material grinding. øC A B Roller mills from Polysius efficiently grind all raw materials for the clinker manufacturing processranging from soft to very hard from dry and fine to very moist and sticky and .

The first 2 Polysius roller mills for slag grinding with optimised housing in China belong to ACC YaDong Cement Corporation. The slag grinding plant in Nanchang is in operation since November 2005. The roller mill is a type RMS51/26 with an SEPOL RMS435 separator.

polysius polycom grinding plant for sale ball mills washingmining manganese processing,quarry, A ball mill is a type of grinding mill, purposed similarly to the . Get Price grinding in cement mill polycom roller press Polysius Polycom Grinding Plant For Sale ...

Polysius Roller Mills. For grinding. roller mill designs for throughput rates of up to and exceeding 600 tph and drive powers ... vertical movement and by pivoting around their ... separator xthe hydraulic system xthe discharge system and the external material circuit xthe feed valve and the feed chute.

Polysius Roller Mills For Grinding. 4 Advantages of Polysius roller mills at a glance xHigh operating reliability and availability as well as easy system handling due to the fact that grinding drying and separation all take place in a single compact unit xConsistently high product quality with minimum. Learn More; Roller Grinding Mill Pdf

mills, but the material is discharged mechanically by a discharge diaphragm. These mills are wellsuited for finer feed materials. They are used for secondary grinding downstream of a primary grinding unit or in a combigrinding system with a polycom ® highpressure grinding roll. Airswept mills are singlecompartment mills.

Polysius Grinding Machines For Kiln Tiers ilvicoletto1563it. hydraulic system in polysius roller mill hydraulic system in polysius roller mill home; hydraulic system in polysius roller mill; consisting of more than 30 machines, sets the standard for our industry get a price hammer crusher animation cement kilns: size reduction and grinding the rosin rammler distribution (rrd) is applicable ...

The Polysius roller grinding mill has used a bucket elevator from the outset for returning the recirculation material. This reduces the amount of airborne recirculation within the mill, which lowers the pressure loss and improves the smooth running of the mill. The bucket elevator is also a great help during maintenance work.

Vertical roller mills are developed to work as airswept grinding mills roller mills are operated with throughput capacities of more than 300 th of cement raw mix loesche mill polysius double roller mill pfeiffer mps mill loesche roller mill and polysius roller mills are widely applied in .

Polysius Roller Mills. For grinding. · uses the testroller mill Atrol (throughput approx. 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills. Roller mill for granulated blast furnace slag grinding in China. Roller mill for cement raw material grinding in China.

News List. Polysius Roller Presss Mill Villanna. Polysius roller mills for grinding roller mills from polysius suited to every applicationroller mill for cement clinker grinding in mexicocoal grinding plant in poland4 advantages of polysius roller mills at a glance xhigh operating reliability and availability as well as easy system handling due to the fact that grinding drying

Sep 26, 2013· 1. Grinding roller of a roller mill, having a roller shaft, a main roller body, and an outer wear ring having wear protection, the connection between the roller shaft and the main roller body being formed by a shrink fit, characterised in that the main roller body is formed by at least 3 or 4 coaxially arranged intermediate rings.

The new roller mill is a significantly more economical solution than the previously used systems at Polysius AG. Even the first mill far exceeded the expected output. According to the operator of the pilot machine in a German cement plant, the mill is a milestone in the field of material crushing. The new roller mill .

Polysius Roller Mills. For grinding 5 The core components of the roller mill include: Read More; Cement Vertical Roller Mill. Cement Vertical roller mill (GGBS plant), cement clinker, raw coal and other raw materials. It gathers grinding, drying and powder selecting as a whole,

In semifinishgrinding, the use of the POLYCOM® leads to energy savings of up to 40 % compared to conventional ball mill grinding systems. In existing plants, the throughput can be increased by over 100 %. In new combigrinding systems, serinnected ball mills can have correspondingly smaller sizes than usual. The material is dried in the ...

Polysius Roller Mills. For grinding Polysius USA. The extensive range of Polysius roller mills provides ... x Very low pressure drop in the grinding system due to optimisation of the gas ... pressure adjustment of the hydraulic system. x Overall ... vertical movement and by .

Polysius Roller Mills For grinding. Roller mill for cement raw material grinding in China. Roller mill for cement clinker grinding in Mexico. Coal grinding plant in Poland. 4 Advantages of Polysius roller mills at a glance xHigh operating reliability and availability as .

Vertical Roller Mill Cement Industry News From Global. thailand siam cement has ordered a lm 5633 cs vertical roller mill from loesche for its cement plant in kaeng khoi the mill will produce mediumfine cement qualities and is designed for grinding clinker gypsum and limestone the c. morethere will; Polysius Roller Mills For Grinding

QUADROPOL® Roller Mill Leading engineering . For instance, the two opposite grinding rollers can be swung hydraulically out of the mill housing; the two roller units remaining in the mill then continue the grinding process. Polysius roller mills integrate three work operations in a single unit: drying, grinding and separating.

May 5, 2014... øC A B Roller mills from Polysius efficiently grind all raw materials for the clinker manufacdemands on a cement raw material grinding... The QUADROPOL® roller mill. The fundamental market demands on a cement raw material grinding plant are high throughput rates and drive power... from the proven Polysius roller mill.

Polysius Roller Mills. For grinding. 4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying. Inquire Now; Welcome to the Bearing Industry Code of Conduct. 27 October 2017 NTN Bearings World Achievement Award.

Polysius Corp. is an industrial supplier of alumina autogenous mill ball mills cement clinker cement grinding cement plants cement raw material clinker coal CemServConsult >> News. Special OfferPlease take a look for this used Polysius ball mill 1

It''s here, then, where Polysius is pushing the benefits of HPGR—or high pressure grinding rolls—as an alternative to other forms of crushing and grinding. But while the Polysius empire was finding ready customers for its new technology in the cement world, finding takers in the minerals business was proving frustratingly slow.

WhatsApp)

WhatsApp)