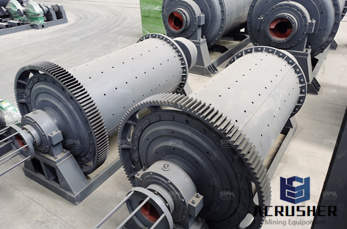

FTM Cement Ball Mill on Working Site YouTube

Sep 03, 2019· The ball mill is the key equipment after the stone or ore materials has been crushed. Processing Ability: –500 t/h Feeding Size: ≤25 mm Applied materials: cement, silicate, newtype ...

WhatsApp)

WhatsApp)

Sep 03, 2019· The ball mill is the key equipment after the stone or ore materials has been crushed. Processing Ability: –500 t/h Feeding Size: ≤25 mm Applied materials: cement, silicate, newtype ...

How To Separate Cement After Ball Mill Stone Crusher. Cement Ball Mill, Cement Mill Used Stone Crushers. Cement mill is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as. Get Price. Grinding Mills Ball Mill Rod Mill Design Parts.

Before After 4. MILL LOAD CONTROL LATEST CONCEPT FOR CEMENT MILL OPTIMISATION Concept M/s Holderbank Engineering, Canada has developed a control strategy for ball mills which can maintain a mill production near optimum, with little operator intervention. The main principle of the concept is that maximum

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

granule separation at the cement mill outlet. 2:51 ... STM SDF Classifier ... Annex B (National Build Standards) separate curtilage for the purpose of these ... Ball Mill:Ball Millis are mainly used to grind materials in mineral, cement, ... on the outlet of Ball Mill, and then negative pressure is formed in the Ball ...

Dec 08, 2009· Re: how to estimate the wear rate for Ball mill. Hey; Ball wear can be measured by weighing an entire charge before and after grinding a known tonnage of materials. With new balls sample of given size can be weighed before and after grinding a given tonnage and, assuming uniform wear per unit of ball surface, the total charge wear can be estimated.

Jun 20, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball Charge

For materials with poor abrasion resistance, it is difficult for ball mill to control the fineness of cement after is the main reason for excessive grinding of cement grinding material used in small grinding test is less, and the grinding time is 80 years, mum sieve residue was still higher than 15%.And ...

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

How To Separate Cement After Ball Mill. Grinding trends in the cement industry Cement Lime . Grinding trends in the cement industry . vertical mills have increased their share to over 60 % and ball mills .

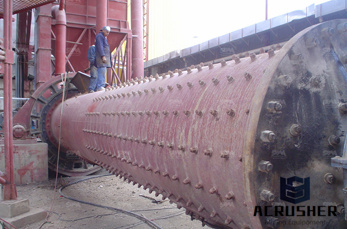

Liner is the main vulnerable part of ball mill, and its use cost is about 2% ≤ 3% of the product price. The performance and service life . ... and the arc length should be wedged with steel plate to separate it. ... and the liner bolt can be fastened again after the cement mortar is solidified.

geometry of cyclone in cement process. How Cyclone Work In Cement Mill. Separator Assembly Work In Cement MillIndia CrusherMill separator assembly work in cement mill php systems/design (portable pipe hangers) is a, Cement mill in cement grinding process in cement grinding station Fine product taken by the airflow is sent to .

The ball mill discharge is feed to the top of the SKSSeparator. Cement grinding capacity of Ball mill increases by adjustment of air gap in the V Separator with proper air distribution. Maintaining uniform air gap between plates and steps in the VSeparator increases production of cement mill.

cement process plant with ball mill in india. Modern cement mill plant · Jaypee Bala Ji Cement Plant, Andhar pradesh In a project of 10000 TPD plant as a process engineer, looking over the commissioning of Cement mill (Ball mill) and commissioning of Coal mill and Raw Mill (VRM) and some of the process fans which are ready for.

Bond ball mill grindability test for overflow wet ball mills. An approach was proposed by Erdem (2002) for dry multicomponent cement grinding ball mills, using the results of the Bond ball mill grindability test. For all model based methods, a reliable method to calculate mill power draw for a

Home >News > Cement Ball Mill Vs Cement Roller Mill Cement Ball Mill Vs Cement Roller Mill Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc.

Cement Mill Chain Scmconnect In. ... How to separate silver after ball mill acherishedbirth mar 22, 2018 this machine works in a re circulating network with ball mill, which can upgrade the and, by watering. Read More; Tsubaki Cement Mill Chains Renamajore.

Ball mill. A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Cement Mill Notebook Scribd. Cement Mill Notebook Free download as PDF File (.pdf), Text File (.txt) or read ... energy consumption and mill outlet before and after replacing worn out balls and ... exhaust kiln gases in a separate compartment until its humidity is below 2%.

Clinker and gypsum for OPC, limestone for limestone cement, and slag for slag cement are all extracted from their respective hoppers and fed to the cement mills. The ball mill grinds the feed to a fine powder in two chambers, namely the first and second chambers.

Ball mill, Ball Machine, Grinder mill, crusher, Ball mill, Grinder mill, crusher, Grinding Mill, Ball mill is the key equipment for grinding after the and the ball mill is widely used in powdermaking production line including cement, silicate, There are ladder liner and ripple liner and .

Ball Mill Ball Mill Appliion Ball mills are the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silie, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of

Ball Mill For Cement Grindingball Mill For Cement Industry. Limestone quarry plant in nigeria bamburi limestone mining crusher dominican small limestone in georgia limestone in georgia suppliers dominican coral stone pool decks stone for wall lime stone mines euipements marble mining in dominican republic granite and limestone quarry crushing plant dominican republic crusher price quarry plant ...

Mar 10, 2011· Re: How Can I calculate new ball size and weight desing for ball mill. Hi, We have a similar mill. Pregrinding with hammer crusher and monochamber mill. Thisis what a proposed based on literture review i did and others agree its more and less correct. But remember it all depends on your mill feed size after pregrinding.

WhatsApp)

WhatsApp)