DIY Melting gold silver Ore on a budget Moon Shiner ...

Oct 06, 2016· PLEASE SUBSCRIBE TO SUPPORT Here we go into basic detail of how to melt your own ore the cheapest and effective ways, with minimal tools, some basic cheap fire power, and in .

WhatsApp)

WhatsApp)

Oct 06, 2016· PLEASE SUBSCRIBE TO SUPPORT Here we go into basic detail of how to melt your own ore the cheapest and effective ways, with minimal tools, some basic cheap fire power, and in .

Sometimes with high grade gold specimens, you have to crush your ore to recover it''s gold..... Gold is often found associated with the mineral quartz. It is sometimes associated with other minerals as well, including iron and manganese oxides, calcite, pyrite and other sulfides as well.

Oct 05, 2012· Hi Dai Uy, because at per oz. of Gold ozs. per Lb. of ore concentrate approx. 636 per oz. of Pd per Lb. of ore concentrate spells 8,300,860 per ton of this type of ore for gold; approx. 839,520 per ton of this type of ore for Pd, plus the Pt 1/5 to 1/4 oz per Lb.

Aug 06, 2015· We had a customer send us some very high grade gold quartz ore which we recovered troy ounces from only 300 lbs! We ran the quartz through our 1/21 ton per hour complete turnkey processor ...

In some cinnabar ores, where the mercury sulfide concentration is high, you can actually see small beads of metallic mercury in the ore. It certainly wasn''t the case with our cinnabar, unfortunately. It theory at least all we needed to do was grind the cinnabar to a fine powder, and heat it gently, whereupon the mercury sulfide readily ...

Jul 13, 2020· In the search for highgrade ore deposits, deep sea and asteroid mining will be increasingly explored by governments and companies. While these technologies will open up new ways for mining companies to optimize the valorization of existing resources or allow access to new ones, they are unchartered territory in terms of business models ...

Cupellation is simple weigh the solid pieces of low grade gold, burn the crap out of it until you get no more slag and it becomes a nice bright yellow bead, and then you weigh it after it cools. My solid low grade gold parts with garbage attached went from 180 grains to grains of high grade gold with no garbage attached.

Sep 12, 2018· The resource is large with a current MI resource of million tonnes of contained Lithium Carbonate Equivalent [LCE], at a very high grade of .

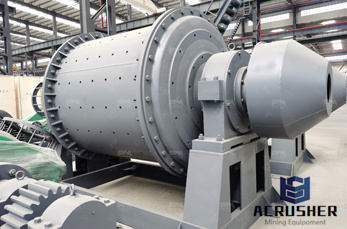

gold ore milling machineryMetro Systems. Gold Ore Processing Mill Crushes Quartz and Mining Rock Ore to Release Gold. Our Gold Stryker ® GS 5000HV is a extreme duty high quality made here in the USA flail impact gold mill that can process and crush up to 5 tons ofinch rock in a day, all the way down to 300 mesh through the mill to release the ...

Jan 01, 2016· Singlelift heaps 10 m high are justified where the grade of ore is high (above g/t), and where the topography allows it. Solution Application Rate, Cyanide Strength, and Leach Time. The timing of gold recovery from ore in a heap leach is a function of five factors: • The rate of gold dissolution. Coarse gold particles dissolve very ...

Lowgrade ore is relatively simple to process while highgrade ore is a more extensive and complicated process. Completing OffSite Refining; Once the initial processing is done onsite, the gold is transported to an offsite refinery to undergo further refining. The purpose of this refining is to remove any remaining impurities. The crude gold ...

Extracting gold from this type of ore is feasible for multimillion dollar mining companies, but almost impossible for the average person to do. Also consider that gold concentrations in ore is never consistent, often occurring in pockets rather than consistently throughout. ... So a mine that produces some highgrade ore will also process tons ...

In direct smelting highgrade concentrate is heated until the gold melts. The liquid is then cooled to form a solid mass of gold dore, a semi pure gold alloy, that can reach upwards of 95% purity. To perform direct smelting, a miner, community mining consortium, or processing shop employs a crucible, a high temperature bowl designed for smelting.

Gold, precious forever but especially lately, is a tricky metal. Bound up in consumer electronics, jewelry and the ores that it comes from, gold is difficult to extract, and most modern processes ...

Dec 18, 2016· Silver is quite different from gold because it is nearly always found within ores that require specialized mining techniques to extract. Silver ore is one of the most important resources on Earth. After processing and refining silver is used for countless industrial uses today. The Main Sources and Uses for Silver Silver is [.]

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different ...

Mining, process of extracting useful minerals from the surface of the Earth, including the seas. A mineral, with a few exceptions, is an inorganic substance occurring in nature that has a definite chemical composition and distinctive physical properties or molecular structure. (One organic

Solvent Extraction and Electrowinning (SXEW) production, virtually nonexistent before the 1960s, reached nearly million tonnes of copper in 2013. (Courtesy of ICSG.) One of the biggest advantages of using leaching is that low grade ores that would be uneconomic to smelt become economic to leach.

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation. This completely updated edition ...

Problem with gold recovery from sulphide ore: How may a mill get the maximum recovery of gold from a sulphide ore, at the least capital cost and at the same time obtain the highest net latter point is most important. In many cases a gold mill using an allcyanide flowsheet with fine grinding of all the ore will report very low gold content in the tailings particularly on an ...

Refining gold from ore or concentrates is done during the smelting process. During this process, flux is used to dissolve contaminates such as metal oxides from the gold. The flux is added to a crucible with the gold that is then melted in a furnace. You can make flux for gold refining by first obtaining all of the ...

highgrade ores contain a larger percentage Most metals are extracted from ores found in the Earth''s crust. It is more expensive and wasteful to extract a metal from a lowgrade ore, but most high ...

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

High Grade Mining Ore Gold Rush Nuggets Learn about how gold ore is valued, and how gold is extracted from ore to ... visible gold present, and only crushing and processing of the ore .

WhatsApp)

WhatsApp)