Discount Steel – Steel Sheet: Hot Rolled, Cold Rolled ...

Buy Metal Online – Steel Sheet: Hot Rolled, Cold Rolled, Galvanized – Order Large or Small Quantity Online – Cut to Size Steel Sheet – No Minimum Order

WhatsApp)

WhatsApp)

Buy Metal Online – Steel Sheet: Hot Rolled, Cold Rolled, Galvanized – Order Large or Small Quantity Online – Cut to Size Steel Sheet – No Minimum Order

From the standpoint of economy, the larger the media the higher will be the liner consumption and media consumption. The minimum size of grinding balls should be selected with caution since there will be a tendency for such balls to float out of the mill in a dense pulp (this is minimised by the use of a grate discharge mill).

colled rolled mill power consumption wildpeppersf 6% higher hot rolling mill output at colled rolled mill power consumption,ingots from the steel plant, especially for cold charged material, to the hot rolling mill, where the utilisation ratio has now risen from 86% to 92%, 7080% due to the lower energy consumption and the absence of .

colled rolled forming mills photos Coldformed steel Wikipedia Coldformed steel (CFS) is the common term for steel products shaped by coldworking processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of coldrolled steel (CRS) are commonly used in all areas of ...

offering light, strong, and pristine ColdRolled Steel Sheets and Coils that meet those demands. We do so by achieving consistent material quality and reducing surface defects with the use of continuous descaling Converter and coldrolled steel sheet and coil mills .

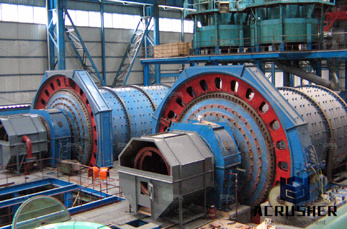

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

The daily Platts TSI US coldrolled coil assessment moved up Wednesday as mills continued to hold offers firm at higher asking prices, according to market feedback. ... Electric Power Ferrous ... A US mill source put current CRC offers between 1,0401,060/st, while a service center source said he was quoted 1,020/st from a minimill producer

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected.

mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential ...

Grain Oriented Lamination Manufacturer,Slit Coils in all available Grades of CRGO and CRNGO,CRGO Grain Oriented Electrical steel are typically used for Distrubution and Power Transformers,India based CRGO Manufacturer offering Transformer Cores and Toroidal Transformer Cores,CRGO Magnetic Cores with Core Frame and insulating materials as per Customers specification and Design,CRGO Grain ...

Tata Steel offers a comprehensive range of coldrolled steel comprising both continuouslyannealed and batchannealed products. This means we can tailor our offer to meet your precise requirements for formability, strength, surface finish or flatness.

Colled Rolled Mill Power Consumption . colled rolled forming mills photos in russia . colled rolled forming mills photos in russia. 99+ customer review . buyers of hot and cold rolled mills mbbain. Read More colled rolled forming mills photos, List of Cold Rolled .

The hot rolled sections have a constant depth, many part of the member, in areas of low internal stresses, and are in excess of design requirements. Frames of PreEngineered Buildings are made from extensive inventory of standard steel plates stocked to the Preengineered Building.

vertical mill power consumption perkinspreschool. Comparison of power consumption of a tworoll mill and a disc mill Power consumption was monitored when light, Munich, caramel and coloring These requirements are most often met by malt mills (roller mills) which. rolled mill power consumption .

Selecting the best RPM for power tapping can be very complicated. There are many variables that must be taken into consideration when selecting the best spindle speed for machine tapping. Among the variables are: Material to be tapped. Cutting speeds need to decrease with the hardness of the material. Length of the hole.

The power consumption per ton can be considerably decreased through proper selection of electric motor since it has been an observation by many surveyors[1] that the selection of electric motor of the rolling mill has been almost five to ten times on the higher side which can be easily verified from the power consumption and motor working data.

coal mill in coke gasification process. coal mill in coke gasification process. Home » coal mill in coke gasification process. A review on the utilization of fly ash ScienceDirect. 1.. IntroductionSince wide scale coal firing for power generation began in the 1920s, many millions of tons of ash and related byproducts have been generated.

By shifting more of the particle liberation to the highpressure grinding roll, substantial savings in power consumption can be achieved. HPGR test results published by Grier (1992) on gold ores from the Mt. Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared to a SAG/Ball Mill .

Modelling and forecasting electricity consumption of Malaysian large steel mills Syazwani Aman*, Hew Wooi Ping, and Marizan Mubin Department of Electrical Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia. Accepted 1 April, 2011 This paper describes a model to forecast the daily maximum demand of Malaysian large steel mills and

When calculating a mill 40 % charge volume is generally used. In pebble and ball mills quite often charge volumes close to 50 % are used. In a pebble mill the pebble consumption ranges from 3—15 % and the charge has to be controlled automatically to maintain uniform power consumption.

roller crusher manufacturerindia colled rolled mill power consumption; small coal fired power plants; the power of rock and rock smash; about the power rating of 4 powermaster grinding machine; gold grinding machine power 4 30 kw; processing of coal power plants; power plant major machinery; material use to make ball mill pulverizer for thermal ...

The iron and steel industry – where we are Total world crude steel production in 2012: 1 542 Mt Energy costs represent around 20 to 25 % of the total input of steel producers and it becomes one of the most important topic of steel producers Coking coal accounts for more than 65% of primary source of energy 4 BF / BOF: % EAF: %

Sep 11, 2014· Customers often ask us about the differences between hot rolled steel and cold rolled are some fundamental differences between these two types of differences between hot rolled steel and cold rolled steel relates to the way these metals are processed at the mill, and not the product specification or grade.

WhatsApp)

WhatsApp)