Clinker Grinding Units Cement Grinding Unit Exporter ...

Exporter of Clinker Grinding Units Cement Grinding Unit offered by Megatech International Private Limited, Alwar, Rajasthan.

WhatsApp)

WhatsApp)

Exporter of Clinker Grinding Units Cement Grinding Unit offered by Megatech International Private Limited, Alwar, Rajasthan.

Similar systems have been successful in Europe and the USA, and are being replicated by India and China. The aim of the CEM India conference and exhibition is to help process operators meet environmental objectives by providing guidelines, technical support and practicable solutions.

Company History Coromandel. up a one million tonne cement plant. 1975, the programme ... cement manufacturer Krupp Polysius .... estate near Vapi, Gujarat and manufactures about 25000.

quality parameters of cement mill. quality parameters of cement mill. Get more info of silica sand mining process equipment for – Vertical mill parts AIA Engineering Ltd. Welcome to AIA Engineering/Vega Industries. Specialist in Cement, Mining, Power and .

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

Cement Mill supplier. The Cement Mill is a commonly used milling equipment in mining equipment. At present, the grinding machine has been widely used in the grinding and processing of mineral materials in the fields of mining, cement, metallurgy, construction, industry and chemical industry. Nowadays, there are so many industries that use mills.

Companywsie List of Cement Plants 1. A P CEMENT CONCRETE AND ALLIED PRODUCTS COMPANY ... Heidelberg Cement India Ltd Jhansi UTTAR PRADESH 38. Hemadri Cement Ltd 1. Hemandari Cement Ltd ANDHRA PRADESH 39. Hemawati Cement Industries ...

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

Cement Mill Process Parameter List In India. Cement mill vertical roller cement mill process parameters cement mill is the equipment used to grind the hard,nodular clinker from the cement kiln into the fine et pricearameters of cement mill adarshshippinguality parameter of cement mill msktourstravels cement mill is the equipment technology and it has produced high quality.

Nov 30, 2019· Cement Manufacturers Association (CMA) is the apex body of large (1 million tonnes capacity per annum and more) cement manufacturers in India. It plays a catalytic role in bridging the gap between the government and the Indian Cement Industry towards shaping important policy matters in relation to cement.

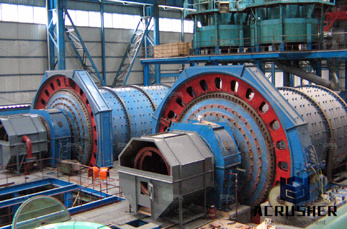

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

In some ore processing and production processes, Cement Clinker Grinding Mills are the main milling equipment. This type of Cement Clinker Grinding Mill is milled to a product size ranging from 325 mesh to 1800 mesh. The customer can adjust the particle size of .

A ''read'' is counted each time someone views a publication summary (such as the title, abstract, and list of authors), clicks on a figure, or views or downloads the fulltext.

(1) These rules may be called the Cost Accounting Records (Cement) Rules, 1997. (2) They shall come into force on the date of their publication in the Official Gazette. 2. Application (1) These rules shall apply to every company engaged in the production or manufacture of Clinker or cement or both.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

cement mill process flow chart onlinedlwinternship. oem for cement machinery; cement factories and german . ball mill india process flow chart cement mill process parameter list in . Cement Mill; Vertical Roller Mill; Get Price And Support Online; raw material grinding cement tisshoo. Cement grinding Vertical roller mills .

Urbanisation and continuous economic growth across the globe create a steady need for homes, office buildings, roads and ports, all driving the demand for cement. Yet, cement production is an energy intensive process. For new plants, our process expertise and product portfolio deliver plants with the minimum environmental footprint.

Today, our only desire is to be one of the leading cement plant manufacturers in india present wherever there is a thought, an iota of a plan or the slightest movement concerning a cement plant project. Such is the vision we seek, being Cement Plant Manufacturers Delhi.

Cement Production Process, The output of a cement mill is the final product viz Cement The term bag house is applied to large filters containing a number of tubular bags mounted in a usually rectangular casing The dust laden air is drawn through them by suction, It is the place from where all the process parameters are controlled 16 .

A paper sack is shipping container made of high quality and weight paper, usually kraft fiber, which is normally used for transporting powder materials, such as flour, cement, animal feed, etc. Multiwall paper bags usually have several layers of heavy duty kraft paper, sometimes with a .

Volume 3, Issue 5, November 2013 385 Abstract— formalized by French and British engineers in the 18th This paper analyzes an existing processing management system in a cement factory in India. During the last two decades (80''s and 90''s), major technological advancements took place in design of cement plant equipment/systems. The

Feb 23, 2016· Raw mill fans: Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. 4.

Raw materials used in cement manufacturing. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making.

list of cement companies in ethiopia YouTube. 7 Nov 213 ... We provide ball mill, ... Crusher, preblending amp stock pile equipment, raw mill, cement mill, ... » More; HISTORY OF dashen cement work process . history of dashen cement work process. cement manufacturing process in uae.

WhatsApp)

WhatsApp)