CoaltoGas Switching: It''s All in the Price

The VACAR NERC subregion, which is made up of portions of ia and North Carolina, is home to a number of coalfired plants with high operating costs and is potentially ripe for coaltogas ...

WhatsApp)

WhatsApp)

The VACAR NERC subregion, which is made up of portions of ia and North Carolina, is home to a number of coalfired plants with high operating costs and is potentially ripe for coaltogas ...

coal preparation plant operating costs immigene. Coal preparation plant Wikipedia. A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded . This has a low upfront capital cost, but much higher operating costs, measured in .

the bottom of the plant to the DMC module which is usually 30–80 meters high above the ground. The pumping energy required therefore constitutes a large proportion of the DMC''s operating cost. As many coal washing plants are built decades ago when electricity is less expensive, no consideration about energy efficiency was made.

clean coal, is highly dependent on the user''s knowledge of the characteristics of the coal to be cleaned. The default case used in this model yields a cost estimate that is considered accurate for the coal characteristics assumed, deviating from a realworld plant only to the extent of price discounts given by equipment manufacturers.

power plant costs. This report analyzes the factors that determine the cost of electricity from new power plants. These factors — including construction costs, fuel expense, environmental regulations, a nd financing costs — can all be affected by government energy and economic policies. Government decisions to in fluence, or not influence,

lall Rlldmall SAIMM. · capital and operating cost plant to be built washing plants where small coal is washed. (There may still be one DWP plant in operation somewhere) The top size of coal being washed is normally between lOmm and One of the major drawbacks associated with the widespread use of Larcodems in South Africa is, unfortunately, its name an

Apr 27, 2013· estimating the cost of coalfired generation – Vista Home Page. For justifying the cost of operating a coal washing plant, a good understanding of the costs and benefits must be obtained. To this end, four coal washing . »More detailed

a single washing device, replacing a previous large coal bath circuit combined with a small diameter cyclone circuit. The use of these high capacity devices coupled with developments in screening and magnetic separation technology could enable a reduced capital and operating cost plant to be built

How Much Does It Cost To Build A Coal Washing Plant? It is easy to ask the question "how much does it cost to build a coal washing plant", but hard to find the right answers. Since there is a standard response to all! This issue not only makes the company''s engineering and Design Institute to go crazy, but it is also a great challenge for many ...

Thermal coal washing • Technoeconomically, pithead power plants using RoM (run of mine) coal have the least Cost of Energy (COE). However, assured supply of consistent quality sized RoM coal will help in optimizing the plant cost and reduce OM problems. • The washing of coal .

Coal Washing Cooperation Required 9Because of additional cost of beneficiation, the washed coal is not yet a favoured commodity for Indian consumers. 9Technical upgradation in the process is required for : • Cost reduction for coal washing • Increase in yield percentage to rejects ratio • Reduction in cost as well as increase in

FLEXIBILITY IN OPERATING CAPACITY. Single stream plants ( with one drum, one cyclone and one spiral section) have operating capacities up to 350 t/h of raw coal feed, though modules are currently under design which will enable a single stream capacity up to 450 t/h.

Sep 12, 2012· After initial washing, the extent to which the coal is . The operating costs of coal cleaning . from one plant to another. The costs of physical coal . lall Rlldmall. capital and operating cost plant to be built Operating results from some of South Africa''s . utilised in all of South Africa''s dense medium coal washing plants where .

Yield % Washing fee Rs/ton 130 Plant Benefits Added Plant and Micro Plant Added Comparative Costs of Supplying Washed Coal of Various Ash Contents at Quantities Required to Provide Equivalent Heat of Base Raw Coal to Varying Distances from the Pithead CLEAN PRODUCT ASH CONTENT RANGE 30% Raw Coal ash Raw Coal Plant Benefits Added ...

coal preparation plant operating costs immigene. Coal preparation plant Wikipedia. A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded . This has a low upfront capital cost, but much higher operating costs, measured in dollars per tonne handled. Get Price And Support Online

Sep 12, 2012· . is changing the way coal preparation plants are built, saving clients'' time and money. Our new designs dramatically reduce clients'' capital costs and operating costs . Physical Coal Cleaning. After initial washing, the extent to which the coal is . The operating costs of coal cleaning . from one plant to another.

HOW MUCH will it cost to build an new coal preparation plant? – HOW LONG will it take? By: Raymond Perr P. E. How often have you been asked "How much will it cost to build?" and "How long will it take? In the coal industry these are often the first questions asked when management is considering a new coal preparation plant or other major capital project.

SADA Group has a proven history of bringing outstanding technical expertise to bear in designing, installing and contract operating coal processing plants for our many clients. Enlisting SADA on your projects is guaranteed to result in efficient and costeffective solutions, delivered with outstanding dedication to customer service.

Coal washing plant operating cost YouTube. Nov 29, 2016 Now chatting: Contact Us: iron ore washing plant operating cost Solution for ore mini. Optimized Pump Systems Save Coal Preparation Plant Money and . own or operate roughly 12 billion tons of steam and metallurgical coal reserves throughout the world. A Motor Challenge Technical Case Study.

DRA Design and construction of coal washing . offer high availability and low operating cost. To date the DRA group have managed in excess of 30 coal washing plant projects and are presently operating 5 of these ...

Coal Preparation Plant impurities with the help of Schenck Process coal washing plants plant design decisions made early in the process will ultimately determine the prep plant''s efficiency operating costs and profitability. Our world class PLANT

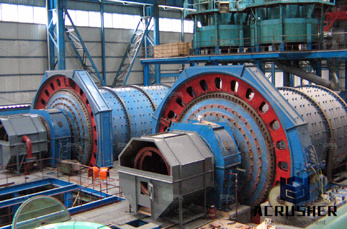

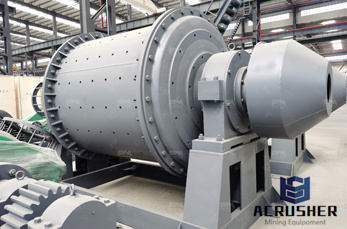

Coal Washing Plant / Coal Preparation Plant. HOT Mining is leading in the design, construction and operation of coal washing plants (coal handling and preparation plants, hereafter "CHPP").. The Joint Venture of HOT – SCCDRI has delivered over 20 CHPPs with capacity from 90 TPH to 3125 TPH.

Coal Washing Plant / Coal Preparation Plant. HOT Mining is leading in the design, construction and operation of coal washing plants (coal handling and preparation plants, hereafter "CHPP").. The Joint Venture of HOT – SCCDRI has delivered over 20 CHPPs with capacity from 90 TPH to 3125 TPH.

of dirt, coal fines and moisture, which eventually add to the problems of coal beneficiation. The fine coal circuits in coal washeries are intricate, needing close attention and careful operation. Increase in fines in raw coal feed to washeries also adversely affects the material balance in fine coal circuits of the currently operating plants ...

WhatsApp)

WhatsApp)