IRD ASSOCIATION, INC

Fall 2019 Meeting October 14th 20th Durant, OK. IRD Association INC. Designing The Future Through Innovation

WhatsApp)

WhatsApp)

Fall 2019 Meeting October 14th 20th Durant, OK. IRD Association INC. Designing The Future Through Innovation

Jun 18, 2014· Long products, roll grooves, Roll pass, Roll pass design, rolling mill, rolls, sections, Roll Pass Design Long products are normally rolled in several passes, whose numbers are determined by the ratio of the initial input steel material (square or round billet or .

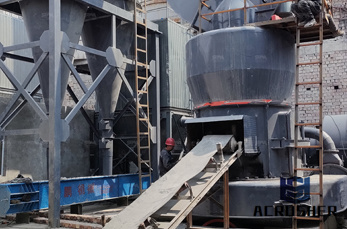

Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (Ibeams, angle stock, channel stock), bar stock, and rails. Most steel mills have rolling mill divisions that convert the semifinished casting products into finished products.

During this time we will cover the basics of metal deformation, the rolling of steel, and Roll Pass Design concepts. The course will provide the participants with the theoretical knowledge, practical skills, and confidence to deal with daytoday roll pass, quality, and production issues.

Capability to manufacture Hot Rolling Mills for Rolling of Stainless Steel, Alloy Steel and Copper as per specific needs of customers. Facility to make Roll Pass Design for rolling of all sections, rolling special profiles and railway tracks etc.

The analysis of two roll pass design options of ten roughing stands atOJSC "MMK" 370 rolling mill has been performed. The usage of a new form of the roll grooves will allow achieving higher durability of the rolls. Lesser rolls consumption will allow saving up to 800K rubles annually. More uniform load distribution by the stands will reduce the possibility of main mill lines equipment ...

Hot rolling of steel consumes immense amount of fuel in power generation and produces considerable environmental pollution. A particular part of this process is roll pass design which is an important engineering issue and continues to be intensely discussed120.

ROLLING MILL EQUIPMENT. ... Having provided over 70 temper/skin pass mills, Butech Bliss can assist customers in selecting the proper mill configuration; and size it specifically for the application. ... This commitment to roll force cylinder design also makes us the perfect supplier for roll force cylinder test and repair services.

Work rolls are usually used as drive rolls. In mill stands where ratio of body length to roll Ø ≥ 5:1, and a very thin alloy steel strip is rolled, and in multiroll machines backup rolls are used as drive rolls. Rolls with antifriction bearings have stepped necks. Mills where journal bearings are used usually have flat roll .

Work experience in a CombiMill that produces more than 250 products.(Flats, squares, angles, beams, channels, coils, rebbar) and Wire Rod from mm to 16 mm Roll Pass Design Guide designing (stripper) Designing of new products and equipment CNC Programming Materialization of the necessary startup process Process control and optimization

Overall scope of supply: • Plant and mill design • New mill equipment • Refurbish existing equipment • New automation system • Roll pass design • Supervision, commissioning and start up Russula designed the mill to roll bars and sections. The new rolling line at Dojran Steel has 18 new housingless stands in an H/V arrangement ...

Our goal at Chicago Refurbishment Company (CRC) is to remain a leader in providing engineering services and products for the steel mill industry. Since 2003, CRC has been servicing mills throughout North America with the goal of growing steel production.

It is a page of the detail of Section Rolling Mill of Steel, manufacturing, installation, sales and aftersales servicing of steelmaking machinery, nonferrous metal producing machinery, and cokemaking machinery as well as related equipment for use in Japan and overseas

However, I will not include any details about roll making the expertise of roll making is a different and very secret story which is not necessary for us to be able to understand rolls. Of course the understanding of material science is applicable in any type of construction, in any steel part;

May 18, 2015· Roll pass design in continuous bar mills 1. African Foundries Ltd. Lagos, Nigeria Presented by Rul Kishore 2. Basics of Rolling A rolling mill consist of several, at least two rolls cylindrical or nearly cylindrical bodies which are termed as "roll" and which rest in bearings at their ends. The normal and average center distance from the center of one roll to the center of o

Apr 12, 2012· BakerRullman Manufacturing Leaders in the design, engineering, and fabrication of rotary drum dryers, bins hoppers, feed seed mills, structural steel, and custom metalwork!

A temper mill is a steel sheet or steel plate processing line composed of a horizontal pass cold rolling mill stand, entry and exit conveyor tables and upstream and downstream equipment depending on the design and nature of the processing system. The primary purpose of a temper mill is to improve the surface finish on steel products. Components

With over 30 years experience with hot rolling mills and OEMs of rolling mill equipment, we have the knowhow to solve your problems and develop new products for you. We pride ourselves for developing the highest quality roll pass design to ferrous and nonferrous hot rolling mills for production of the most challenging sections.

Roll pass design . 5. Rolling mill speed calculation ... Rebar quality control . Suitable course for mechanical engineers, steel mill supervisor, technicians and those are interested about physics, math, metallurgy. Who this course is for: Student of Mechanical Engineering, Maths, Physics and Steel ReRolling Mill Technicians, Supervisors etc ...

Roll Pass Design; Full pass design revamp. A mill in the US was rollilng suboptimally due to multiple product mix changes over the years. Russula codeveloped a new pass progression with technical experts from the mill. More information

Oct 18, 2017· ️First of all, Happy diwali to all my subscribers and viewers as well.️ Hello guys, I welcome you again in this new fresh topic. This topic is regarding the rolling process used for ...

Dec 24, 2018· The workpiece passes through the bottom and intermediate rolls, and returns between the middle and top rolls. Various steel roll manufacturers provide topquality roll mills to meet every type of industrial requirement. High Rolling Mills The Four High Rolling Mills have a roll stand with four parallel rolls placed one above another.

Steel Mill Engineering. From Concept to Creation – Onestop shop for your engineering needs. GMB Heavy Industries is proud to be among the highly respected companies in the metal and steel industries, that provides a wide range of steel mill engineering and design services.

steel mill roll and pass design engineering a rational roll pass design for a rolling mill, it is neces For example, the roll pass designs used to roll round steel bars 25–105 mm in diameter and hexago Roll cooling systems Kark A properly designed roll cooling system is one of the major criteria for a long pass life and high ...

WhatsApp)

WhatsApp)