Widely Used cement grinding mill process plant with low ...

Widely Used cement grinding mill process plant with low consumption_OKCHEM Please note that all emails sent by OKCHEM are from ***, servicemail., or notifications

WhatsApp)

WhatsApp)

Widely Used cement grinding mill process plant with low consumption_OKCHEM Please note that all emails sent by OKCHEM are from ***, servicemail., or notifications

Past Project: Conversion of open circuit cement mill to closed circuit one (Heidelbergcement Georgia Rustavi cement plant) Position on Project Project Manager

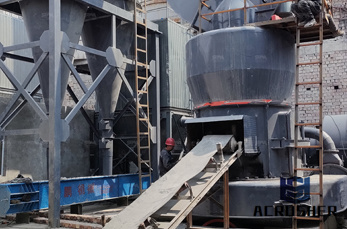

A cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into. The cement mills on a cement plant are usually sized for a clinker consumption considerably grea

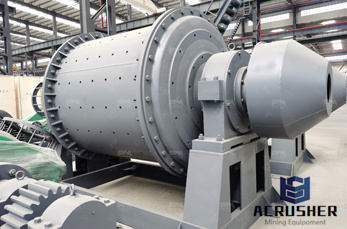

The specific energy consumption of a ball mill is greater than a vertical roller mill (VRM) that performs the same operations by a factor of between and 2, depending on the degree of optimization of the ball mill. Finish Grinding System. The common cement grinding systems are summarized in Figure 1 and can be divided up into three main groups:

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant.

Extensive sampling campaign was performed around the cement grinding circuit of a cement plant in Turkey, for different production types of cement, as CEM I, CEM II //, for the ...

Con grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker. The advantage of Con medium is its ability to increase mill capacity because of its interlocking shape and increased density per cubic foot of grinding charge.

7 Cement grinding and storage In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill (one Closed circuit ball mill in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type of

Vertical cement mill cement plant,ball mill,vertical ... The company specializes in manufacturing ball mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast ...

China Dia 20mm150mm Grinding Alloy Media Ball for Mining and Cement Plant, Find details about China Forged Steel Balls, Ball Mill Steel Balls from Dia 20mm150mm Grinding Alloy Media Ball for Mining and Cement Plant Shandong Shengye Grinding Ball Co., Ltd.

Products. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

There is many Equipment are used for feeding system. Hereby we are consider feeding equipment which are used in rotary kiln raw material feeding, VSK Feeding Equipment, Ball mill Feeding Equipment. In Industries Equipment selection is most critical part, if any not consider proper selection of feeding Equipment it will create critical plant process.

Coal Grinding Mill In Cement Plant Coal Grinding Mill In Cement Plant. Coal grinding mills all industrial manufacturers videos find all the manufacturers of coal grinding mills and contact them directly on ball mill for coal grinding vertical fcb emill fives cement minerals plant coke plant germany 1x impact hammer mill phm2028mvd coal 700 th rotor.

a. To keep smooth operation of plant and handle emergencies. b. To keep in mind the quality of product. c. To manage work force on different work places during the shift. d. Two Kiln each having capacity of 5800T/day with inline precalciner system. e. Two Loesche gringing mill (vertical) for raw material grinding each with capacity of 10320 T ...

Cement mill . A cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into . The cement mills on a cement plant are usually sized for a clinker consumption considerably grea . Get Price; cement grinding optimisation zenith. However in the cement industry the grinding process is more of an There are ...

Feb 10, 2016· planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare ...

Plant Manager Bamburi Cement Ltd Nairobi Grinding Station . Sep 2018 – Present 1 year 10 months. Nairobi . ... Production Manager at Mabati Rolling Mills. Fredrick Okoth. ... Plant Manager at national cement company paver block division, Nairobi,Kenya. Raphael Masha.

Types Of Coal Mill Used In Cement Plant Types Of Coal Mill. LUM vertical roller mill is used to pulverize and dry coal before it is blown into the power plant furnace in the coalfired power plants.; As we all know coal production line is with serious pollution, In order to provide a environmental friendly coal grinding mill for customers, MTW trapezium mill is designed with sealed structure.

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations. 25 años en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de moliendas de cemento y .

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

By 2019, SBM has built 6 advanced manufacture bases which cover a total area of over 1,200,000 m2, contain various of crusher and grinding mill production line, such as sand making machine, mobile crusher, vibrating screen and Raymond mill, etc.

Pfeiffer says a ready2grind system it supplied to Petra Cement started in early December 2019. The clinker grinding mill is operational at a grinding plant on the Zamboanga Peninsula in Mindanao. No value for the order has been disclosed. Petra Cement''s sister company, Big Boss Cement, has also ordered a modular mill system from Gebr. Pfeiffer.

Commissioning of grinding unit (Chinese Make), 600t/day capacity of cement ball mill, osepa separator, Waxi Haver packer, cement packing plant capacity of 480,000 t/annum Feb 2013 – Feb 2013 Successfully commissioned.

Ordinary Portland Cement will be ground on a mill of the type MVR 3070 C4 with a capacity of 70 t/h. The mill will be equipped with a highefficiency classifier SLS 2650 BC. The grinding plant has a very compact design and can also be used for the grinding of mixed cements with granulated blastfurnace slag and/or fly ash.

WhatsApp)

WhatsApp)