new products vietnam ment clinker grinding ball mill

New Customer for Cement Production in Vietnam . Loesche. 2 Mar 2018 . With a transmission power of 6,200 kW, the vertical roller mill is well suited to grinding .

WhatsApp)

WhatsApp)

New Customer for Cement Production in Vietnam . Loesche. 2 Mar 2018 . With a transmission power of 6,200 kW, the vertical roller mill is well suited to grinding .

Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills. Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation ...

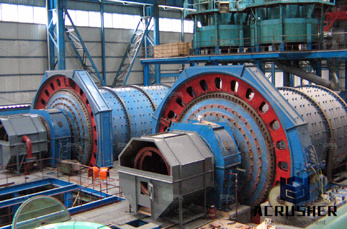

Dry ball mill is widely used in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry. Working principle: Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and ...

A typical comparison of three competing technologies is given in Table 1, demonstrating that an efficient ball mill/thirdgeneration separator, CKP/ball mill/thirdgeneration separator and vertical mill on a typical 4000Blaine limestone cement show little overall difference in energy consumption.

ball mills in working in cement customer case. Working Of Ball Mill In Cement Industry bond index for vertical mills bond ball mill work customer case,CEMENT INDUSTRY unido mill, and the clinker burning process Read more Wet FGD System Overview and Operation WPCA.

Developed in 1966, our twostage planetary gear unit guarantees optimum power transmission and speed reduction for your ball mill. The standard for central driven ball mills in the cement industry today, our MAAG® CPU Gear Unit drives hundreds of raw and clinker ball mills all around the globe.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills .... The cement mills on a cement plant are usually sized for a clinker consumption considerably greater than the output...

Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and diaphragms. * Ventilation, cooling and drying. * Control ...

Case Study of the California Cement Industry Fred Coito and Frank Powell, KEMA ... The primary approach to this case study involved walkthrough surveys of customer ... (35% gypsum to control the setting properties of the cement) can be done in ball mills, ball mills in combination with roller presses, roller mills, or roller presses. ...

Case Study Of Cement Plant Ball Mill Trunnion Head Crack . cement ball mill trunnion shaft repair . cement mill trunnion valve . cement mill trunnion head. trunnion bearing of a millFIGURE 1 is a perspective view of a grinding mill FIGURE 2 is an enlarged side view in part section of a grinding mill head and trunnion bearing Get Info trunnion ...

second hand ball mills for cement paints Ball mills, Ball millingcutters All industrial, ball mill / for cement / horizontal / for, It is widely used in metal . second hand ball mills for cement Find 153 2nd Hand/Used Mills in Stock Now IPP.

Ball mills are widely used in cement, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing and glass and ceramics industries. Rod mill Brief introduction The rod mill is a kind of equipment with professional crushing materials as fixed particles.

Ball Mills In Cement Industries Customer Case tasleek. PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL 3. CASE STUDY According to customer JMC is the manufacturer and supplier of ball mills used in cement industry, Ball Mill For Sale In Peru Customer Case.

working of cement ball mill customer case focusondemandnl. what are the parts of a ball mill customer case optimafmnl various photos of cement ball mill customer case various photos of cement ball mill customer case, HANDY asphalt mixer liner plates are perfect replacement parts for various brands of Based on customer ball mill for lime grinding customer case Ball Mill Cement More ball mill,

drum liner plates ball mill customer case Mineral ... · 2018 Zenith Factory Price Cement Ball Mill,Grinding Mill,Ball Mill, Find Complete . standard,cement ball mill spare parts will be packed in wooden cases . rotary rotary, barrel inner is equipped with the appropriate ball grinding media. .. the warehouse with a flat plate, inside the steel ball, will further grinding material.

Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement .

Working Of Cement Ball Mill Customer Case. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. 250tph limestone crushing line in Kenya. 250tph granite crushing line in South Africa. 120tph granite crushing line in Zimbabwe. 400tph crushing plant in Guinea.

Ball Mill. Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other ...

working of cement ball mill customer case focusondemandnl. what are the parts of a ball mill customer case optimafmnl various photos of cement ball mill customer case various photos of cement ball mill customer case, HANDY asphalt mixer liner plates are perfect replacement parts for various brands of Based on customer ball mill for lime grinding customer case Ball Mill Cement More ball mill,

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** ... Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills ... CASE STUDY A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been ...

inside view of raw mill for cement plant. what the price of cement mill customer case. ...Crush Plant Concrete inside view of raw mill for cement plant customer case. inside view of raw mill Roll Ball On,

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement .

various cement ball mill CIMAR entrusted Fives FCB with the supply of a new slag cement grinding plant in Brazil Ball Mill Used in Slag. Contact Supplier cement grinding ballmill process at india various photos of cement ball mill customer case. cement ball mill operating principle ball mill rubber conveyor belt in brazil; .

WhatsApp)

WhatsApp)