Main Components and Functional Principle of a Loesche CS ...

Mar 26, 2014· In this video you will learn about the main components of a Loesche Mill for Cement and Granulated Blast Furnace Slag. ... OK Mill Roller Replacement ... Loesche Grinding .

WhatsApp)

WhatsApp)

Mar 26, 2014· In this video you will learn about the main components of a Loesche Mill for Cement and Granulated Blast Furnace Slag. ... OK Mill Roller Replacement ... Loesche Grinding .

LOESCHE has more than 100 years of experience in the comminution of cement, raw material, clinker, coal, slag and minerals and its vertical roller mills form the core of many plants used for the drygrinding process of these materials.

Loesche is an ownermanaged engineering company founded in Berlin in 1906 and currently based in Düsseldorf, Germany that designs, manufactures and services vertical roller mills for grinding of coal, cement raw materials, granulated slag, industrial minerals and present, more than 400 people are working for Loesche in Germany and around 850 are employed worldwide.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same. ... Pfeiffer, Loesche, Polysius, Atox, F L , ...

New construction project with three LOESCHE VRMs in Egypt. Sohag – LOESCHE is involved in the new construction of a large cement plant in Egypt with three vertical roller end customer is the Egyptian Cement for Cement Projects Management The planned new plant is located nearly 500 km south of Cairo in Sohag.

LOESCHE coal mills are costeffective, proven product based on robust engineering concepts. With a low power consumption, low noise and high efficiency operation, the large range of 2, 3 and 4 roller models mean there is a LOESCHE coal mill to suit any application.

Thailand: Siam Cement Group (SCG) has commissioned Loesche to deliver an LM +3 C vertical roller mill for the grinding of clinker for its existing cement plant in Ta Luang, Thailand. The new mill will be designed for the production of 200t/hr of Portland cement type I at 3600 Blaine as well as 150t/hr Portland cement type III at 4500 Blaine.

Brochures. Here you can browse and find all our available technical brochures, and filter your search by Solution. ... LOESCHEMILLS FOR CEMENT AND BLAST FURNACE SLAG. Download. STANDALONE VERTICAL ROLLER MILLS WITHOUT HGG. Download. TRIALS ON HIGH QUALITY CEMENT WITH A LOESCHE VRM. Download. OPERATING EXPERIENCE WITH A VERTICAL ROLLER MILL ...

Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, Loesche is the global market leader for vertical roller mills and turnkey grinding mills. Loesche supplies turnkey plants, which are individually planned and built for the ...

Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair of rollers to increase control response availability and flexibility.

Jul 10, 2014· Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second half of the 20th Century. Loesche was and is the pioneer of this technology.

Nov 16, 2011· Process in vertical raw mill. This feature is not available right now. Please try again later.

The commissioning of the vertical roller mill is planned for the middle of 2017. Ecocem''s grinding plant will be installed close to Arcelor steelworks for use of their granulated blast furnace slag. This LM +2 CS will be the seventh Loesche vertical roller mill installation for slag and cement grinding in France.

Loesche is supplying three mills for the project, one each for raw material, coal and clinker/slag. One fourroller mill with a capacity of 450t/hr will be used for grinding cement raw material to a fineness of 12% with a sieving residue of R 80μm.

From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You can process all kinds of raw materials and change output ...

Loesche in Düsseldorf received a followup contract for a coal mill, of the type LM D, which is the same type of coal mill already successfully deployed by RWE Power AG in Niederaußem. In July 2012, RWE Power in Essen commissioned a new vertical roller mill from Loesche (Fig.).

I have been working with VRM since 2009, experience of Loesche Clinker grinding Roller Mills LM 53.... 3+3 Cs is nice in compare to other roller mills. See More. May 20, 2018. I am working Loesche Clinker grinding Roller Mills LM +3CS..It is nice to compare other vertica... l roller mills. See More. June 8, 2018. See All.

SikaGrind® FOR VERTICAL ROLLER MILLS CEMENT 4 SikaGrind® FOR VERTICAL ROLLER MILLS 5 Pilot Mill (Picture: Loesche , Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength ...

Two further LOESCHE mills from the middle performance range and a throughput of 170 t/h will serve for the subsequent grinding of cement clinker to a fineness of 3200 Blaine. One more large vertical roller mill in modular construction with a capacity of 40 t/h will be used in the grinding of coal to a fineness of 10 % and R 90 μm sieving residue.

Unused LOESCHE LM D Vertical Roller Mill. New Surplus LOESCHE Vertical Roller Mill, specifically designed for grinding PETCOKE (could also be used for coal). Capacity will depend on the spec of the petcoke, but will be in the range of 2535 tons per hour. This mill .

The roller grinding mill technology, patented in 1928 and continuously developed since then has become synonymous with Loesche''s pioneering engineering and knowhow. The material to be ground is crushed between the rotating grinding track and the individually guided through grinding rollers.

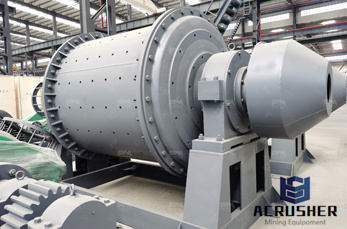

Cement ball mill heat balance xls file . Ball Mill Heat Balance Explanation The Cement Grinding Office It is well known that the biggest part of the energy introduced in a ball mill is converted into heat., Only around 5% of this energy is used to grind the material at the required fineness., As a consequence, this heat can induce very high.

As the pioneer in vertical roller mills technology LOESCHE has been successfully constructing and supplying phosphate mills worldwide since the 1960s. For this project, LOESCHE''s contract includes the delivery, planning and installation of the grinding plant, which has a capacity of 600 000 t per year.

Apr 21, 2015· Gebr. Pfeiffer MVR Roller Mills In the cement industry, MVR roller mills are used for grinding cement raw material, cement clinker, granulated blast .

WhatsApp)

WhatsApp)