Ball End Mills MSC Industrial Supply

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting edge and used in ...

WhatsApp)

WhatsApp)

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting edge and used in ...

7/8" 2Flute HSS SingleEnd Ball Mill, 7/8" Shank, : 7/8" 7/8" 2" 4 1/4" : EMR32 Details: 1" 2Flute HSS SingleEnd Ball Mill, 1" Shank, : 1" 1" 2 1/4" 4 3/4" : EMR32W Details: 1" 2Flute HSS SingleEnd Ball Mill, 3/4" Shank, : 1" 3/4" 2 1/4" 4 3/4" : EMR36 Details: 1 1/8" 2Flute HSS Single ...

D. Sumanth Kumar, ... Mesh, in Synthesis of Inorganic Nanomaterials, 2018. Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell.

Type "D" Ball and Pebble Mills. One of the most popular designs, the Type D mill is available as a steel ball mill with or without steel plate wearliners, or as a lined ball or pebble mill utilizing Alumina, Buhrstone or rubber linings. Type D ball and pebble mills are available in a variety of standard sizes from 15 inch to 8 foot diameters.

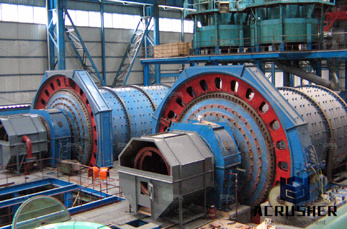

Ball mill introduction. The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Ball mill can grind various ores and materials with dry type or wet type.

2020 New Type Saving Ball Mill Cement Bottom Price Efficient Grinding Ball Mill , Find Complete Details about 2020 New Type Saving Ball Mill Cement Bottom Price Efficient Grinding Ball Mill,Efficient Grinding Ball Mill,Ball Mill Cement,Saving Ball Mill from Mine Mill Supplier or ManufacturerJiangxi Shicheng Mine Machinery Factory

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Aug 25, 2014· The ball mill contains a hollow cylindrical shell and that will rotate about its axis. These cylinders are filled with the balls that are made up of stainless steel or rubber, to crush the material contained in it. 5. Horizontal Ball Mills. • Horizontal ball mills are the most common type in the industry.

Opening the ball mill box reveals a user''s manual, a mill base, two mill jars, and five extra drive belts. Unpacking the Ball Mill The ball mill jars The first thing that struck me when I first looked at these mills was the nice quality of the mill jars. These things are really heavyduty, and have a very solid closing and sealinglid assembly.

Introduction : Grid type ball mill is the traditional grinding equipment for all kinds of ore regrinding, widely applied in the fields like mining, metallurgy, refractory materials, construction, environmental protection, and chemical industry, etc. Product Improvement : Barrel rubber linings is of high wear resistance, long service life and convenient maintenance.

Aug 19, 2018· You can be easily identified as ball cutters as their end is hemispherical in shape. Ball cutters are used to decrease the stress concentration and are also known as ball end mills. Whenever there is a need of cutting threedimensional shapes then, there is a use of ball cutters to perfectly cut those threedimensional shapes. 6. Involute Gear ...

The ore discharge of overflow type ball mill mainly depends on the pulp itself high over the lower edge of the hollow shaft bushing. 2. Performance and application differences between grid type ball mill and overflow type ball mill. Compared with the overflow type ball mill, the ore discharge of grid type ball mill is lowlevel forced discharge.

May 30, 2020· The ball mill is a kind of grinding machine, which is the key milling machine used after the material has been crushed, and it also has a mixing effect. This type of grinding machine has a cylindrical body with spherical grinding mediums and materials.

Working Principle Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

Ball mill, a mill using balls to crush the material Bead mill a type of Mill (grinding) Burr mill or burr grinder, a mill using burrs to crush the material, usually manufactured for a single purpose such as coffee beans, dried peppercorns, coarse salt, spices, or poppy seeds

Home / ball mill / Em Type Coal Mill Operating Procedures. Email: [email protected] Related products. ... inc is the leading manufacturer of solid fuel solid waste biomass wood coal gas oilfired steam and hot water boilers,Em Type Coal Mill Operating Procedures. Live Chat.

Jun 14, 2020· We are considering as one of the top most company manufacturing and exporting batch type ball mill. June 14, 2020 +, info Home

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

China Low Cost Grid Type Ball Mill Machine Price, Find details about China Ball Mill, Small Ball Mill from Low Cost Grid Type Ball Mill Machine Price Shandong .

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

This article on choosing milling media for a ball mill by Ned Gorski is a side article that goes with the "Ball Milling 101" Media Cautions. In his book Ball Milling Theory and Practice for the Amateur Pyrotechnician, Lloyd includes a section on casting your own lead media.

HQMaster 40pcs End Mill Combination Kit 1/8" Shank CNC Router Bits set Cutter Cutting Milling Tool (4 Type, Each 10Pcs) Including Flat/Ball Nose Four Flutes End Mill 10°/20° Vshape Engraving Bits

The E max is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. faster and finer grinding than any other ball mill;

WhatsApp)

WhatsApp)